Introduction to Audi 5 Cylinder 10V Turbo Engines

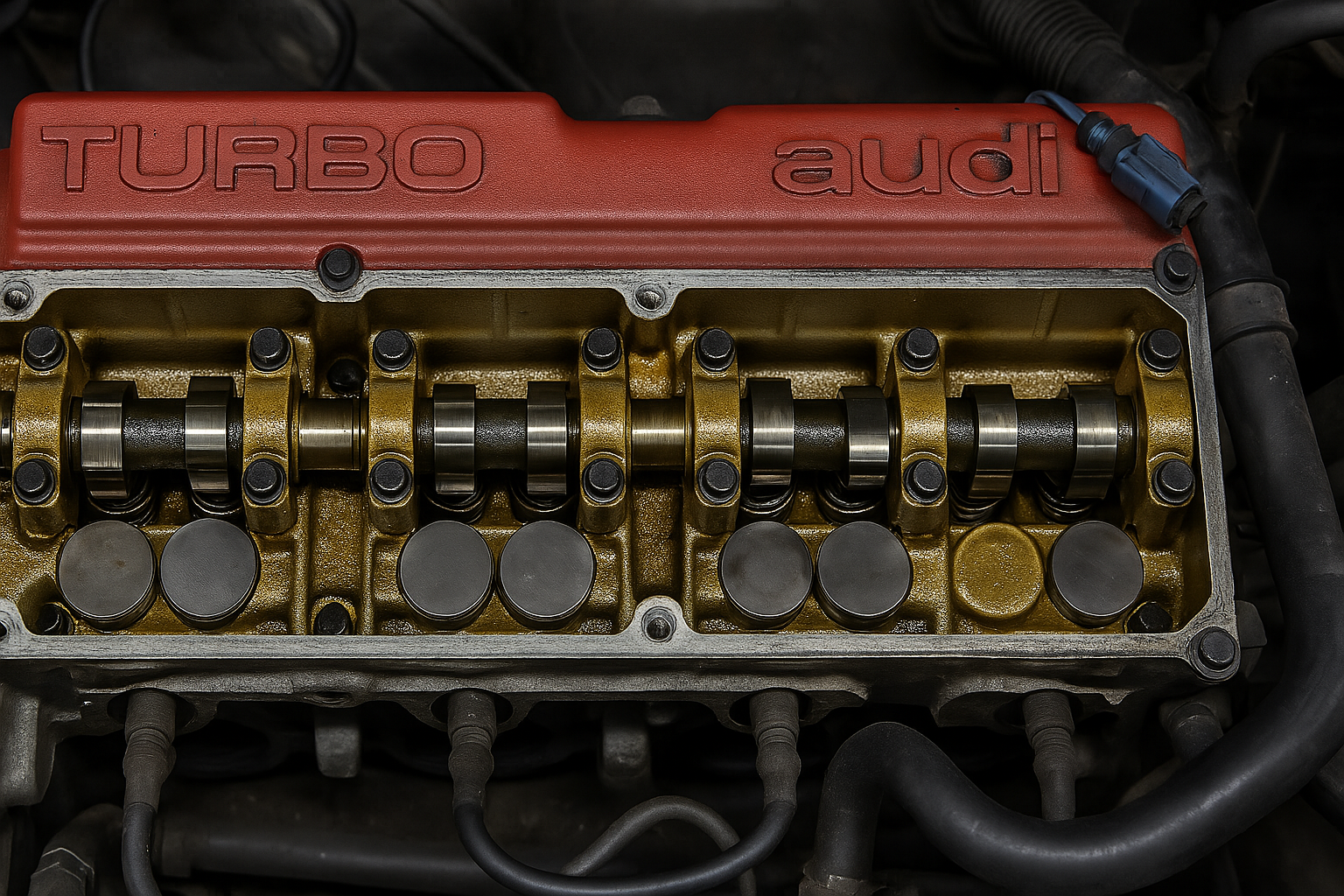

audi 5 cylinder 10v turbo valve shims Audi’s five-cylinder engines have a legendary reputation in the automotive world. First introduced in the late 1970s, these engines quickly became known for their unique sound, performance, and reliability. Among the most iconic variants is the Audi 5 Cylinder 10V Turbo engine, particularly featured in classic models like the Audi Quattro. These engines combined robust design with turbocharging to create thrilling performance even by today’s standards.

Maintaining such a classic engine requires understanding its internal components, especially when it comes to valve train components like valve shims. These tiny parts play a big role in keeping your Audi engine running smoothly.

What Are Valve Shims and Why Do They Matter?

Valve shims are thin, precisely measured discs used to adjust the clearance between the camshaft and the valve lifters. In the Audi 5 Cylinder 10V Turbo engine, which uses a mechanical lifter setup, valve clearance is crucial to proper engine performance. If the clearance is too tight or too loose, it can result in poor fuel efficiency, increased wear, and reduced engine life.

The correct clearance ensures that valves open and close at the right time and with the right amount of force. This directly impacts combustion efficiency, power delivery, and overall engine health. In a turbocharged engine, where internal temperatures and pressures are higher, maintaining correct valve clearance is even more critical.

Also Read: What is the Cultural Significance of Muhalabieh

The Importance of Proper Valve Adjustment in Turbo Engines

Turbocharged engines like the Audi 10V Turbo produce significantly more power and heat than naturally aspirated engines. This extra power can place more stress on the valvetrain. Valve shims are vital in compensating for wear in the camshaft, lifters, and valves over time.

If the shims are not replaced or adjusted as needed, the engine may develop a ticking noise, misfires, or reduced performance. In some cases, improper valve clearance can lead to burnt valves or valve seat damage, resulting in costly repairs. Regular inspection and adjustment are part of smart, long-term turbo engine maintenance.

How Valve Shims Work in the Audi 5 Cylinder 10V Turbo

The Audi 10V Turbo engine uses a bucket-over-shim design. This means the camshaft lobes act directly on a “bucket” or tappet that contains the shim. This design allows for greater precision in high-performance applications but requires shims to be of the exact right thickness.

Each valve in the engine will have a required clearance specification, usually provided in the factory service manual. During inspection, if the gap between the cam lobe and the tappet is not within spec, a thinner or thicker shim must be installed to bring it into tolerance.

This process often requires removing the camshaft, depending on the engine model, although some tools allow shims to be swapped without full disassembly. The key is measuring carefully and selecting the correct shim from a shim kit, which typically comes with a range of thicknesses in 0.05 mm increments.

Must Read: Understanding the Trenton 126lb Mouse Hole Anvil Identification

Symptoms of Incorrect Valve Shim Adjustment

Owners of classic Audis with the 10V Turbo engine should be aware of several signs that might indicate a need for shim adjustment. A common symptom is a ticking or tapping sound coming from the valve cover area. This can indicate excessive clearance. If the clearance is too tight, the engine might run rough when cold or have trouble idling.

Another red flag is a loss in engine power or decreased fuel efficiency. This could be due to valves not opening or closing properly, which disrupts the combustion process. In worst-case scenarios, incorrect shimming can lead to burnt valves or even piston-to-valve contact in engines with high lift cams or modified timing.

How Often Should You Adjust Valve Shims?

Valve shim adjustment on the Audi 10V Turbo isn’t needed as often as oil changes, but it’s a crucial part of long-term maintenance. Audi’s factory recommendation usually falls around every 60,000 miles, though high-performance or heavily driven engines may require checks sooner.

In engines that are rebuilt, modified, or used for racing, it’s a good idea to check shim clearance more frequently. Heat cycles and mechanical stress can accelerate wear, making regular inspections a wise choice.

Checking valve shims involves removing the valve cover and measuring the clearance with a feeler gauge. Based on the measurements and current shim size, a new shim is selected and installed.

Finding the Right Valve Shims for Your Audi

Sourcing the correct valve shims for your Audi 10V Turbo can be a challenge, especially with older vehicles. Audi and Volkswagen used a common 33 mm diameter shim in many models, but not all shims are interchangeable. It’s important to get a shim kit specifically for the 10V engine to ensure proper fitment.

There are aftermarket shim kits available that include a range of shim thicknesses. OEM shims are ideal, but high-quality aftermarket options from trusted brands also perform well. Keep in mind that buying individual shims can get expensive over time, so a complete kit is a better investment if you plan to maintain the engine yourself.

Tools Required for Valve Shim Adjustment

Adjusting valve shims isn’t overly complex, but it does require the right tools. You’ll need a feeler gauge to measure the gap, a micrometer to measure the thickness of shims, and possibly a special tool to depress the tappet and remove the shim. Some DIY mechanics use magnets to lift shims, though care must be taken not to scratch any surfaces.

A torque wrench is also necessary for reinstalling components to the correct specifications. If the camshaft must be removed, proper timing tools and diagrams are critical to avoid misalignment during reassembly.

Professional vs DIY Valve Adjustment

For those experienced with engine work, adjusting valve shims on an Audi 10V Turbo can be a satisfying and manageable task. However, for less experienced owners, it may be best left to a professional. Mistakes in measuring or reassembling can lead to expensive damage, especially in interference engines where valve-to-piston clearance is tight.

That said, many Audi enthusiasts take pride in maintaining their own engines. With patience, the right tools, and careful attention to detail, a DIY shim adjustment is entirely achievable and can help keep the engine running at peak performance.

The Legacy of the Audi 10V Turbo Engine

The Audi 5 Cylinder 10V Turbo is more than just a powerplant; it’s a symbol of Audi’s engineering innovation. From rally stages to street performance, this engine has proven its reliability and potential for tuning. Keeping such an engine in top shape is a labor of love for many enthusiasts.

Valve shims may seem like a small detail, but they play a vital role in maintaining that legacy. Whether you’re restoring a classic Quattro or driving a modified 200 Turbo, understanding and adjusting your valve shims ensures your Audi runs strong for years to come.

Conclusion

Maintaining valve clearance in the audi 5 cylinder 10v turbo valve shims engine is an essential part of preserving performance, reliability, and engine longevity. Valve shims, though small, have a big impact on how the engine breathes, responds, and lasts. Whether you’re a dedicated Audi enthusiast or a new owner of a classic turbocharged five-cylinder, keeping an eye on valve shim condition should be high on your maintenance checklist.

Regular inspections, proper tools, and attention to detail will help ensure that this iconic engine continues to deliver the thrilling performance it’s known for. Don’t underestimate the power of precision—especially when it comes to something as legendary as the Audi 10V Turbo.

FAQs About Audi 5 Cylinder 10V Turbo Valve Shims

What is the correct valve clearance for the Audi 10V Turbo engine?

The ideal valve clearance varies slightly depending on the model and year, but typically intake and exhaust clearances should be around 0.15mm to 0.25mm when cold. Always consult your specific engine’s service manual for exact specifications.

Can I reuse old valve shims when adjusting clearance?

Yes, if the existing shim provides the correct clearance, you can reuse it. However, worn or damaged shims should always be replaced to ensure consistent performance.

How do I know which shim thickness to use?

Measure the valve clearance with a feeler gauge, subtract the difference from the desired clearance, and adjust shim thickness accordingly. Use a micrometer to confirm shim size before installation.

Are aftermarket shim kits reliable for classic Audi engines?

High-quality aftermarket kits are generally reliable and cost-effective. Look for kits with a wide range of sizes and positive reviews from Audi or VW community members.

Can valve shims affect engine performance?

Absolutely. Incorrect shim sizes can lead to poor combustion, reduced power, misfires, or even engine damage over time. Maintaining proper clearance ensures smooth engine operation.

Do I need to remove the camshaft to replace valve shims?

It depends on the engine and the tools you have. Some tools allow shim replacement without camshaft removal, but in many cases, especially with early 10V engines, removing the camshaft is required.

How often should I check the valve clearance in my Audi 10V Turbo?

Audi recommends checking every 60,000 miles, but high-performance or aggressively driven engines may need inspections more frequently.